Having purchased an all-mode, all-band (160m - 70cm) transceiver, I became curious about what 2-meter weak signal operations have to offer. I have a 5/8th over 5/8th vertical collinear antenna hanging in a tree at some 30 odd feet high, but I never heard anything on it, except on FM. The reason for that, I learned, is most 2-meter weak signal operations take place using horizontal polarization. Cross polarization is good for about 20 dB attenuation, which easily translates into the difference between perfectly good copy and inaudible signals. So I decided I needed a horizontal polarized antenna.

As is usually the case with antennas, there are a bazillion designs to choose from and none of them really fulfills all your requirements. I do not have a mast or tower, and I love to use trees for supports, so I wanted something that I could hang from a tree branch. Since I have no means to rotate the antenna, I required that the new antenna have an omnidirectional radiation pattern. It didn't have to be the best performer, because I just wanted to get my feet wet in this new mode of operation. There are few designs that would fit that bill. I settled on the Halo antenna because of its small footprint. This is important because larger designs would require a longer branch, with sufficient clearance in all directions, to hang from. The Halo I describe here has a diameter of only about 12 inches and can be hung virtually anywhere in a tree.

The Halo Antenna

Halo stands for "HAlf wave LOop". The antenna is in fact nothing else but a half wavelength dipole with the legs bent in the shape of a circle. However, the ends do not meet, (especially near the end of the month) so technically it's not a loop. This loop can be fed with coaxial cable using a gamma match.

The Halo is certainly not a new design. Laurence M. Leeds and Marvel W. Scheldorf obtained a patent for this antenna in 1943. You can find their design at the U.S. Patent Office under Patent Number 2324462. Click on the "Images"-button to view the patent. You'll need a special browser plugin to access the patent. See the U.S. Patent Office website for more information on this.

Most Halo designs you find on the internet have moving parts. Often they require some sort of tuning capacitor and have a capacitor in the gamma match along with a slider construction that connects the gamma arm to the radiator. I prefer a design without moving parts so that the antenna doesn't get detuned easily when a bird decides the antenna makes a good resting place. I found the design that I describe here in a German antenna book "Antennen Buch" by Karl Rothammel, Y21BK.

Basic Design

The design of this antenna is very simple and straightforward. It basically consists of a half wavelength piece of copper tubing bent into a circle. Between the ends of the tube there needs to be a gap of at least 1 3/16". This is to minimize capacitive coupling between the ends. This antenna is fed by a coax feed line through a gamma match. The gamma match is constructed from 6 1/4" #4 or #6 copper wire. This wire is bent into an L shape. The short end of the wire is soldered on the inside of the loop at the point where the long end of the gamma arm aligns with the halfway point of the loop. See below:

You could feed the loop directly with 50 ohm coaxial cable as shown above. However, I added a 1:1 current balun (choke) to the original design. I did this to force all the RF current, on the inside of the braid of the coax feed line, to go into the antenna and not to come back down on the feed line on the outside of the coax braid. This will help keep the feed line from radiating, causing potential RFI problems and changing the radiation pattern of the antenna.

Building the Halo

Building this antenna is like making the pieces of the puzzle first, and then putting the puzzle together. First you build the antenna itself, then the support boom, the choke balun, the mount, and finally, you put these parts together.

The Antenna

Start out by cutting a string to a length of 41 inches. You'll use this to measure the correct tube length. Thick monofilament wire as used for garden trimmers works very well. Mark this wire at the halfway point. A piece of electrical tape will do fine. This is the point where you’ll later have to mark the copper tube and where the coax braid will get soldered to the tube.

You'll probably find the soft copper tubing material in a 10-foot length, coiled up in a bag. Fortunately, the coil diameter is about the same diameter as the final loop will be. So there will be very little bending involved to get the circle shape needed for the loop. Eyeball how much tube you'll need from the loop coil and cut it. Don't attempt to make an exact measurement yet. In fact, the measurement I give here for the main loop is deliberately somewhat too large anyhow. Put the part you cut off on a flat surface and now measure how much you really need using the string from the previous paragraph. Cut off the excess tubing. Use the string again to find the halfway point of the tubing and mark it. This will be the point at which you will later solder the coax braid. Make sure the tubing is shaped like a circle, and that the ends are at least 1 3/16" apart. To keep the ends apart, I cut a piece of hexagonal Bic pen tubing to length and put it between the ends. You can secure it with some shrink tubing, but don't shrink it until you're done with the final tuning later on.

Now build the gamma from a piece of #6 or #4 copper wire. Use the measurements from the detail diagram above and bend it as shown. Solder the short end of the gamma arm to the inside of the loop at the point where the long end of the gamma arm lines up with the halfway point on the main loop (as marked earlier).

The Support Boom

To support the antenna, I used a piece of 3/4" schedule 40 PVC pipe. Lay the antenna on the pipe and cut it so it's just a bit longer than the diameter of the loop. Now drill holes through the pipe to mount the antenna. On one end of the pipe you need two holes approximately 1 15/16" apart for the main loop and the gamma match to go through. Make sure you drill the hole for the tube very close to the end of the PVC pipe. This will make it easier to solder the coax braid onto the copper tube. Also be careful not to drill the hole for the gamma match all the way through the pipe. The gamma match only goes in halfway through the pipe and will not come out the other side.

On the other side of the PVC pipe, drill a hole in the same plane as the first two holes for the piece of plastic tubing (hexagonal Bic pen) that is being used to keep the ends of the main loop apart. Next, drill the holes necessary to mount the SO-239 (panel mount) connector.

The last hole you need to drill is for mounting purposes. This hole needs to be drilled in the middle of the PVC pipe, all the way through. Make absolutely sure that this hole is perpendicular to the plane of the antenna. This hole needs to be the size of a bamboo skewer you can buy at the grocery store (sold in a bag of 20 or so). This skewer is later used to mount the antenna. You can use something else if you like as long as it's thin, strong, sturdy and straight.

The Balun

Even though the original design does not call for a balun, I decided to add a 1:1 current balun in order to prevent RF currents from flowing back onto the outside of the coax braid, perhaps causing the feed line to radiate, create interference and change the radiation pattern of the antenna. The balun I built for this antenna consists of 12, 1/2" long, type 43 ferrite beads that slide over a short piece of RG-58 coax with the outer jacket removed. The hole in the beads I used was not big enough for the coax to slide through with the outer jacket intact.

The length of the piece of coax needed for the choke can be measured from the end of the boom where the gamma match is to the farthest edge of the SO-239 connector, plus about 3/4". The balun itself is about 6 inches long. If you use a different size of beads, just make sure you have enough beads to make a 6-inch long balun. You can secure the beads with some shrink tubing or electrical tape. This should be enough to make an effective balun for VHF that can handle up to 100 Watts of power.

One side of the coax should be prepared so you can solder it to the SO-239 connector. You can already solder the connector to the coax if you wish. The other side needs to be prepared so that the braid will reach the middle of the loop, and the center conductor meets the gamma match. Do not cut the center conductor to length. Instead, only remove the insulation from the center conductor so that it can be soldered later to the gamma match. Leave the excess wire intact. Put some shrink tubing or electrical tape around the braid to insulate it, except for the very end, of course.

If you do not have any ferrite beads available, you can construct an air core choke balun instead. There are several ways to make one. One method is to wind about 7 turns of the feed line on a coil form made from 3/4" PVC pipe. Place this choke near the antenna. If you prefer the choke to be part of the antenna, then you can wind 7 turns of the coax going from the SO-239 connector to the gamma match around the PVC boom.

The Mount

Since I've chosen to hang this halo from a tree branch, I needed to find a way to mount this antenna onto a rope coming down from a branch in such a way that the antenna itself will remain in the horizontal plane. I came up with a method that will use gravity to hold the antenna perfectly horizontal.

When you built the PVC boom, you drilled a hole in the middle for a skewer. Now imagine you put the skewer through the boom, put the support rope alongside of the skewer and then tie the rope to the skewer with some wire ties. If you'd hold just the rope above the skewer and boom, the boom would just dangle in all kinds of directions and stay far from being horizontal. However, if you'd make a small loop in the bottom end of the rope and hang a weight from it, you'll see that the boom stays perfectly horizontal. See the diagram below.

Putting It All Together

Take a piece of pen tubing, or whatever you chose to fill the gap in the main loop, and push it in the PVC boom.

Next you can join the antenna with the boom. Take one end of the antenna and guide it through the hole next to the hole for the gamma match in the PVC boom. Slowly move the tubing through the PVC support pipe. You'll notice some resistance because the loop is round and the holes through the pipe are in a straight line. This causes some friction. With a small amount of force you'll see that that the tube will go through the pipe quite easily. Stop when you reach the gamma match. Do not push the gamma match into its hole in the boom yet.

Bend the end of the braid of the coax that goes inside the boom at a 90-degree angle. Just over 1/4" from the end should be sufficient. This will make it easier later on when you solder the braid to the tube. Also bend the exposed center conductor at a 90-degree angle about 1/4" from the end.

Slide the coax inside the PVC boom through the hole for the SO-239 connector. While you do this make sure that the end of the center conductor kind of scrapes on the inside wall of the pipe, on the side where the hole for the gamma match is located. At some point you'll notice that the wire will get caught in this hole. Pull the wire through the hole with needle nose pliers while you continue to slide the coax inside the pipe. Stop when the insulation around the center conductor appears at or through the hole. If you bend the wire a bit at this point, it will stay in place.

Solder the center conductor to the gamma arm. You can cut off the excess wire, but I simply bent the remaining wire along the gamma match. Or, wind it around the gamma match, just in case you have to do it again. Now slowly push the gamma arm in the hole of the PVC boom. If it doesn't quite fit, you can cut a tiny wedge out of the hole where the center conductor passes through the hole. Stop when the gamma match reaches the middle of the pipe and the center marking on the copper tubing is in the middle of the PVC pipe.

When you look into the pipe you'll see the braid near the copper tube on the inside of the pipe. Pre-tin the copper tubing at the halfway mark. Make sure this mark is in the middle of the pipe. Now you can solder the braid to the tube.

If you haven't already soldered the SO-239 connector to the coax, then do so now. Push the remaining coax into the boom and fasten the SO-239 connector to the boom.

Slide a piece of shrink tubing over each end of the antenna. Mate each end of the copper tube with the piece of pen tubing protruding from the support boom and slide the shrink tubing back a bit so it covers the piece of plastic tubing also. Do not heat the shrink tubing yet. This will hold the ends in place. You can also use electrical tape to do this. Just make sure the ends of the copper tubing stay flush with the plastic tube.

Mounting the antenna

The antenna is now finished and we're ready to mount it for testing and tuning. Find a place where you can hang the support rope, like a tree branch. Make sure that there are no metal objects nearby, as they will detune the antenna. You can tune the antenna at a different place than the final destination if you wish.

Put a wire tie just below the middle of the skewer. This will prevent the antenna from sliding down the skewer. Secure the bottom half of the skewer onto the rope with two or three small wire ties. Make sure the skewer cannot slide along the rope. Drop the bottom end of the rope through the loop of the antenna and push the skewer all the way through the support boom from the bottom up. You may have to wiggle it a little bit when you're halfway into the pipe in order to get past the coax inside. Once the skewer is all the way through the support boom and the boom is resting on the wire tie on the middle of the skewer, you can fasten the top half of the skewer to the rope with two or three wire ties.

Your antenna can now dangle freely from the rope. You'll see that the antenna does not really stay horizontal yet.

Make a small loop at the bottom end of the support rope and hang a weight from it. I used a brick. Even if the antenna is going to be mounted very high up in a tree, try to keep the weight near ground level. This serves two purposes. First, if for some reason the weight would fall, it will not fall on top of someone and no one will run into it. Second, it will keep the whole system very stable in the wind. If the weight would be higher than just a few feet of the ground, the wind would catch it also and start swaying the weight. Not only is this dangerous, it will also take a long time before the system is stable again once the wind drops.

Of course you could opt not to use a weight and simply tie the bottom of the rope down. However, that makes the whole mechanical system very inflexible. The rope would move back and forth over the branch when it's swaying in the wind, and eventually the branch might be cut.

If you later find that the rope and weight are swaying too much, you can minimize this with a guide rope that is tied to, say, a post, or the trunk of the tree, and goes around the support rope. The guide rope will then allow the support rope to move mainly in the vertical direction.

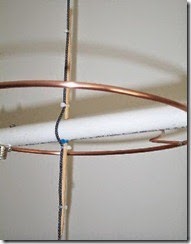

Once finished, the antenna should look something like this:

Testing and Tuning

Before you test the antenna, double check you made all the right connections. When you use an ohmmeter to check the connections, you should be measuring a short (zero ohm resistance) between the center and outer connections of the SO-239 connector. This antenna is what is called "DC grounded", which may help reducing static buildup on the antenna.

Now you can attach a 50-ohm coaxial feed line to the antenna to test and tune it. Use a wire tie to attach the feed line to the skewer. This will make the feed line run along the support rope and help stabilize the system. If you plan on weatherproofing the antenna, then read the part on weatherproofing below first before you tune the antenna.

I borrowed an antenna analyzer to tune the antenna, but you can also do it with just an SWR meter. When you use an SWR meter and cannot find a near 1:1 SWR anywhere in the 2 meter band, you need to make note of three SWR measurements. One at 144 MHz, one at 146 MHz and one at 148 MHz. If you find that the SWR is lower at 144 than at 146 and 148 MHz, then you know the antenna is tuned below the 2-meter band. If you find that the SWR is lower at 148 than at 146 and 144 MHz, then you know the antenna is tuned above the 2-meter band.

You will probably find that the antenna is tuned somewhat below the 2 meter band. I deliberately listed the measurement of the main loop slightly too large which results in a lower than desired resonance frequency. Cut a tiny bit of each end of the copper loop until your antenna resonates near 144.200 MHz. That is the SSB calling frequency in the U.S.A. Of course you'll have to decide at which frequency you want the antenna to be resonant. The 1:1.5 SWR bandwidth of the antenna is about 1 MHz.

Since the gamma match is fixed, you will probably not be able to get an exact 1:1 SWR reading. More realistic is 1:1.1 to 1:1.3. Don’t let this scare you. SWR readings other than 1:1 are perfectly fine as long as they do not go much higher than 1:1.5. At that point many rigs will throttle back the power. If you really cannot sleep peacefully if the SWR isn't perfectly flat, then by all means desolder the gamma match from the loop and solder it at a different point until you've found that serene 1:1 SWR spot. I will warn you though that things can get messy real quick while it really isn't worth the effort.

If you find yourself in the position where you cut too much of the antenna ends in order to find that elusive 1:1 SWR, don't panic! There's an easy solution. Solder a half inch or so piece of solid copper wire (#14 will do) to the inside of each tube end as shown in second diagram on this page. The wire ends protruding from the copper tubing will fit inside the plastic separator tube. This will help maintain a clean look of the antenna while you get a second chance at tuning the antenna. Now simply cut small pieces, like 1/16" or so each time, off of each wire until the antenna resonates at the desired frequency.

When the antenna is tuned you can heat up the shrink tubing around the copper tube ends so that everything remains in place.

Weather Proofing

You can weather proof the antenna by filling all holes and gaps with RTV, or silicone sealant. Care should be taken when you want to seal the end of the boom where the ends of the loop meet. Putting RTV in that side of the pipe will detune the antenna. Make sure the sealant only goes to the inside of the PVC tube, and don't be tempted to put any sealant on the loop ends. The reason for this is that there is some stray capacitance between the loop ends. By adding sealant you change the dielectric between the tube ends, and therefore the value of the stray capacitance. This in turn changes the resonant frequency of the antenna. So it is better to seal this end of the support boom first before tuning the antenna if you plan on weather proofing the antenna.

If you feel that you need to seal the area around the small piece of spreader tubing, then use something like a very thin layer of nail polish. Also, if you want to make the loop very shiny, use some very fine steel wool to polish it.

Conclusion

I described how you can build a Halo antenna for two meters that does not require a mast, has a very low part count and can easily be built with a minimum of tools. This project description may seem more complex than similar ones you can find on the internet, but that is simply because most other plans leave out a great deal of detail, especially in the area of construction. I like to include the lessons I learned along the way when I built the antenna.

This article also described a unique way to mount these types of antennas on a rope. This makes the antenna an attractive alternative for use in the field where the usual support structures may not be available or for those folks who, like me, do not have a tower or mast. Of course you can mount the antenna on a mast with a U-bolt if you wish.

I have built a 2 and 6 meter version of this antenna, mounted them on the same support rope and feed them with separate feed lines.

The 2 meter Halo is mounted at 24 feet, and the 6 meter Halo is mounted at 20 feet high. As you can see, the Halo makes for a stealthy antenna even though that was never one of the design goals. If you really want the antenna to blend in with the background, paint it light gray or light green, and add some random black strokes here and there. When you break up any symmetrical lines and patterns, any object can be made invisible against the background.

These Halo antennas allow me to dabble a bit in VHF weak signal operations given the restrictions mentioned in the beginning of this article. While the performance of this type of antenna is limited compared to other types of antennas, I'm rather surprised with the DX contacts I’ve been able to make with a modest 50 Watts of power.

If you have any questions or suggestions, please do not hesitate to drop me an email.

73,

--Alex, KR1ST

Discover all the information about the product Digital hazemeter haze-gard plus - BYK Gardner and find where you can buy it rhopoint.

ReplyDelete